One of our new favorite things is the “Retrotechtacular” column on Hackaday. The writers for the series do a great job digging up vintage, kitschy media that highlights the bleeding edge of technology from yesteryear. Industrial films can get hammy quickly, but we enjoy the sense of optimism that accompanies tech, no matter the time period. Even though the video we have for you today is nearing its 100th birthday, that optimism is palpable.

General Electric made an industrial short in the 1920s, a silent film that shows how the company produces porcelain insulators for power lines. We were shocked when we learned exactly how many steps in this process were done by hand. Hackaday writer Kristina Panos describes the process:

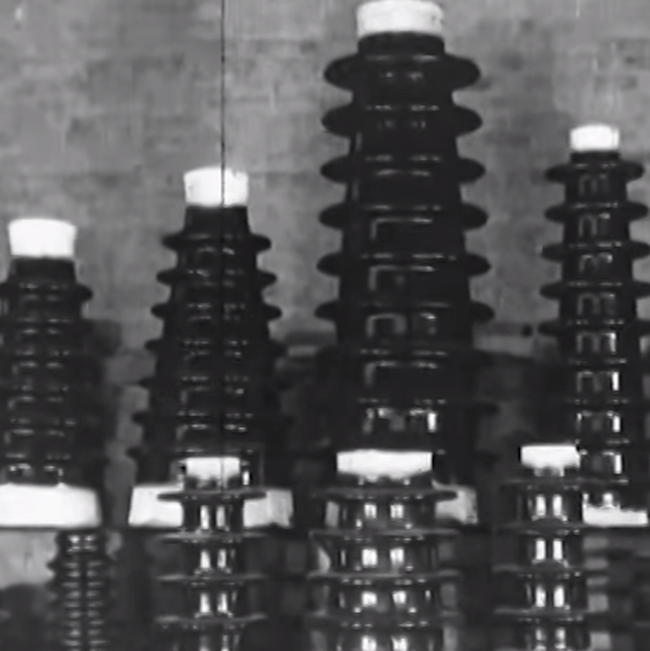

Porcelain insulators of this time period were made from china clay, ball clay, flint, and feldspar. In the dry process, ingredients are pulverized and screened to a fine powder and then pressed into molds, often with Play-Doh Fun Factory-type effects. Once molded, they are trimmed by hand to remove fins and flashing. The pieces are then spray-glazed while spinning on a vertical lathe.

Other types of insulators are produced through the wet process. The clay is mixed in a pug mill, which is a forgiving machine that takes scrap material of all shapes, sizes, and moisture levels and squeezes out wet, workable material in a big log. Chunks of log are formed on a pottery wheel or pressed into a mold. Once they are nearly dry, the pieces get their final shape at the hands of a master. They are then glazed and fired in a giant, high-temperature kiln.

The video was uploaded by YouTuber Jeff Quitney, who accompanied it with a wealth of technical data.

Intent is a fun thing to puzzle over, since this short comes to us from film’s infancy. It must have had a sense of novelty, more than we ascribe to commercials today. Was this a training video? A way to get laborers interested in working for General Electric? A PR stunt using a highly techy new media?

The handmade angle invites a comparison between the other process videos we’ve posted on this site, the studio pottery videos in particular. In light of those, it’s odd to see workers making these components so passionlessly. The workers in the film are quick, precise and bereft of emotion. It’s a step or two away from the factory scene in Metropolis. There’s probably a Marxist critique somewhere in this video.

Speaking of critiques: If you have any regarding this video of (barely) contemporary ceramics, post them in the comments.

Is there any way to get a copy or view this video? My grandfather was the foreman of the Porcelain department for GE at Schenectady. He was a master potter from Italy and helped populate the department with his countrymen. He and they worked in wet clay to make some huge insulators but my grandfather also created vases and plaques as art pieces for the management on special occasions. Please share my email if someone has interest in contacting me.

Excellent video – thank you for posting – loved seeing the ‘industrial handmade’ of past and a bit sad to know these skills are now lost (?). So interesting to see them press mold with hydraulics as well as manually by hand. Also intrigued by their single fire technique (make, spray with glaze and fire once). Finally – wow – what massive kilns!

I don’t think it is fair to accuse them of being bereft of emotion. To me they seem like expert craftsmen. I suspect that they were quite proud of their skill. If anything they play up to the camera to show their professionalism. Especially the “wet” potters.

All I can think about is DUST! and no respirators! Times have certainly changed. This film is amazing.

That was the formost thought I had, that respirators were not used in even one part of the entire process. I wonder what the health statistics were for GE ceramic workers?