LOS ANGELES, CALIFORNIA — Researchers with UCLA and Missouri S&T recently overcame an engineering puzzle to create a lighter type of metal.

The American Ceramics Society recently reported that scientists found a way to evenly spread ceramic nanoparticles through metal, creating a material that is surprisingly strong and lighter. Cutting metal with ceramics is not a new idea, but a hang up has always been ceramics’ tendency to clump together rather than spreading throughout the metal. In their experiments with silicon carbide nanoparticles and a magnesium-zinc alloy, the scientists created a homogenous mixture that they hope can be scaled up for industrial use.

The American Ceramics Society reports:

The scientists started with a low concentration of nanoparticles, adding just 1% by volume silicon carbide nanoparticles into the molten alloy. Evaporating the alloy within a vacuum furnace concentrated the nanoparticles, resulting in a final composition of ~14% silicon carbide and ~86% magnesium, the team reports in Nature.

“The evenly dispersed nanoparticles provide strength throughout the metal and improve plasticity simultaneously,” Chen says in the MS&T press release.

According to the UCLA release, homogenous distributed silicon carbide gives the metal record specific strength and specific modulus, and the metal nanocomposite retains excellent stability under high temperatures, too.

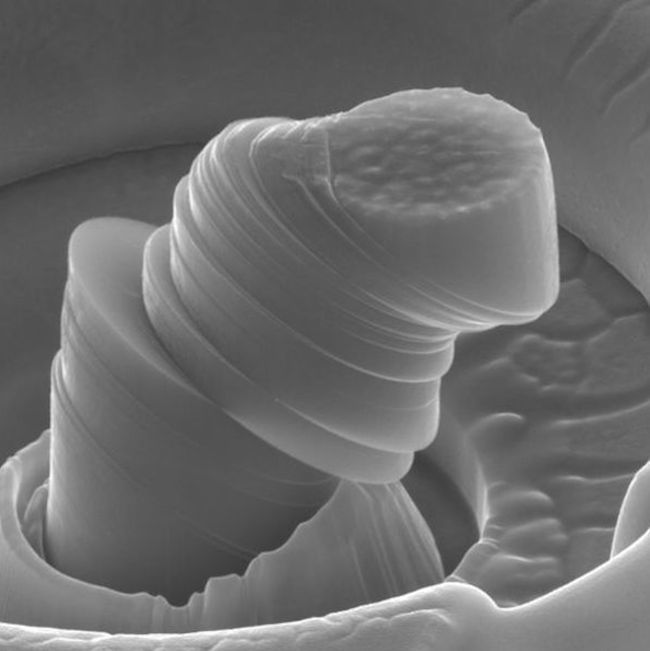

You can see their results in the images we included in this post. The featured image is plain ol’ magnesium. The next image is magnesium with silicon carbide nanoparticles. Each of those tiny pillars is just four micrometers across. Looking at it with a microscopic eye gives one a better idea of the scientists’ goal: the ceramics are clearly buttressing the metal.

More research is required, but hopefully we’ll see more of this fascinating project soon. If you enjoyed the microscopic images, you can see more here.

What do you think of this use of contemporary ceramics? Let us know in the comments.

Add your valued opinion to this post.