We picture the science writers over at The American Ceramics Society as large, disembodied brains floating in blue-and-white porcelain vases. They’re back again with another writeup of ceramics at the bleeding edge of scientific research.

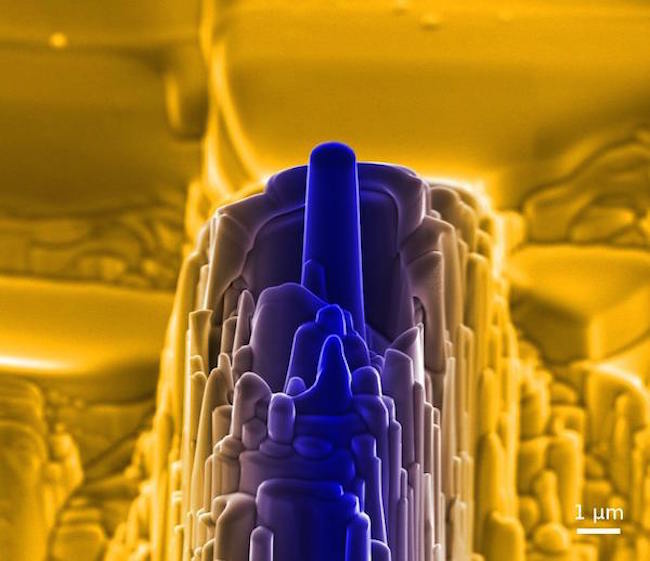

Above image: Electron micrograph of a micrometer-scale carbide pillar carved out of a single crystal using focused ion beams. Credit: Lawrence Berkeley National Lab

Apparently researchers at the University of California have been studying “ultrahigh temperature ceramics” under electron microscopes, allowing them to ponder their makeup at the atomic scale. By seeing how the crystals in substances “slip” at room temperature, the researchers believe they have discovered a thread that could lead to the production of ceramics that are hard enough to withstand rigorous applications such as aerospace flight, but are ductile rather than brittle. Ductility, according to Wikipedia, is a materials science term that refers to a solid material’s ability to deform under tensile stress, often characterized by its ability to be stretched into a wire.

The society explains the implications of this research in a post that is moderately free of jargon:

So what do the observations mean?

“These results could help engineer the microstructures of ceramic components to tailor their mechanical properties,” Kodambaka says in a UCLA press release.

Via email, he elaborated a little further: “One can, in principle, use all of this new information to design polycrystalline transition-metal carbides with proper grain sizes and grain orientations that are most conducive for plastic deformation at room-temperature. It is also known in the literature that the mechanical properties of these carbides depend sensitively on their composition. Therefore, it is possible that, by choosing the appropriate alloying elements, ductility can be increased while retaining mechanical strength—i.e., make tough ceramics.”

But, Kodambaka, warns, that may not be as easy as he makes it seem.

“Both of these, however, are not trivial tasks and will require an iterative combination of multiscale modeling and experimental synthesis and testing studies to identify the optimal microstructures and compositions that will lead to high toughness. Probably an easier goal is the fabrication of thin (sub-micrometer) and flexible membranes made of these materials for miniature structural components for MEMS and NEMS devices.”

However, the possibilities stretch much further. Ductile-yet-hard ceramics would be superior materials for aerospace applications of all sorts, radiation-resistant foils for solar sails, and more.

To Kodambaka, the research has been an exciting example of scientific discovery.

“For me, the exciting part of this research was the fact that we were able to find something new and surprising using conventional uniaxial compression tests on single crystals of ZrC and TaC. There are several other crystal orientations and other transition metal carbides on which such studies could be conducted and new phenomena discovered. Couple this with the fact that these carbides can exist as sub-stoichiometric compounds (i.e., C-vacancies) with stoichiometry-dependent properties and that one could synthesize myriad alloys of these carbides, possibilities of finding new information are endless.”

Any thoughts about this post? Share yours in the comment box below.

Add your valued opinion to this post.