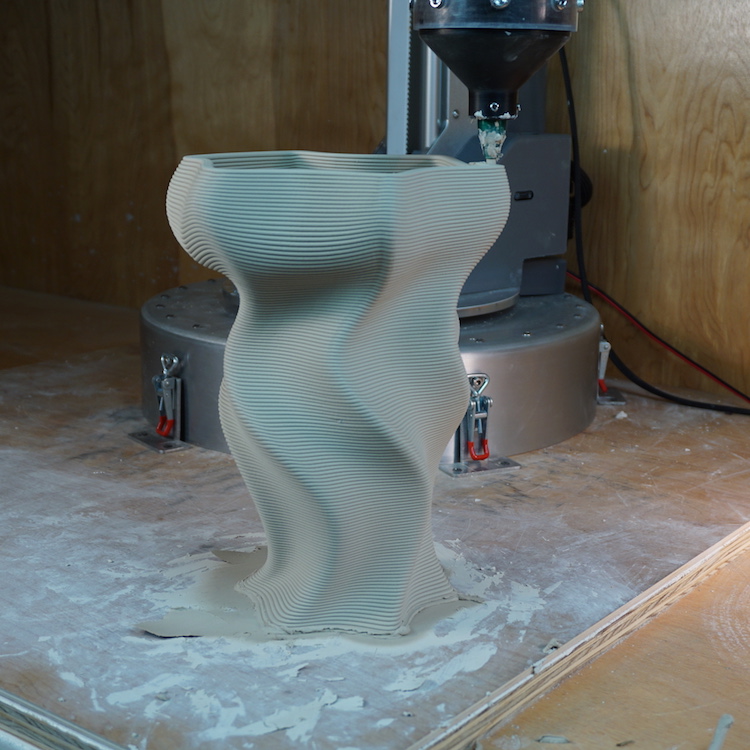

3D Potter, the largest US manufacturer of 3D ceramic printers, and Emerging Objects, announced it has made the largest 3D ceramic printer made to date.

Our new PotterBot XLS- 1 is the first large scale Scara robot type 3D printer able of creating objects up to 9 feet tall and 9 feet wide using real clay.

3D Potter and Emerging Objects have joined forces to introduce a new innovation in robotic ceramic/paste extrusion additive manufacturing technology. The Potterbot XLS-1 represents a huge leap in innovation with build dimensions and speeds, which facilitate large scale printing as well as multiple object manufacturing.

Its enormous build envelope has the capacity to print objects up to 9 feet tall and diameters up to 9 feet (3m X 3m)! Whereas typical printers must be larger than the objects they print, accounting for space and portability issues, it’s unique ability to print in 360 degree continuous rotation allows you to 3D print an object larger than the printer itself, offering the potential to print architecturally scaled objects.

The printer also has the unique ability to sequentially print multiple objects for mass customized production. Because the printer is designed for both consumer and more heavy-duty operations, it can either carry a 3600ml container of clay, or can be connected to a larger extruder that can hold up to 250 lbs of clay. The large-scale peristaltic pump attachment can handle non-stop continuous extrusions with nozzle sizes up to 1 inch.

It is the first commercially available large-scale ceramic 3D printer that uses full-body clay. However, the printer isn’t limited to clay. Other materials, such as polymers, concrete, and food-based materials, are also possible with this robust machine.

Constructed from aircraft grade 6061 aluminum, the printer utilizes CNC and welded components for maximum strength and rigidity.

The main rail components are IGUS precision guide rails with hybrid closed-loop stepper motors with on-board computers with telemetry that continually update their position for zero error positioning. This means very precise prints with no backlash or jittery movements at realistic speeds. The drivers are designed for maximum rigidity with extreme accuracy.

Watch this baby in action:

Text (edited) from 3D Potter.

Do you love or loathe this technological advancement from the world of contemporary ceramic art and contemporary ceramics? Share your thoughts in the comments below.

The designer in me likes the shapes possible, but the potter/ceramic artist in me deplores the lack of hands on process and skill set.

I bet they said, once it’d printed large, ‘we’re gonna need a bigger kiln’.

Amazing how far the technology has come in so little time. This is awesome! Love the name, too….Potterbot! Yup.