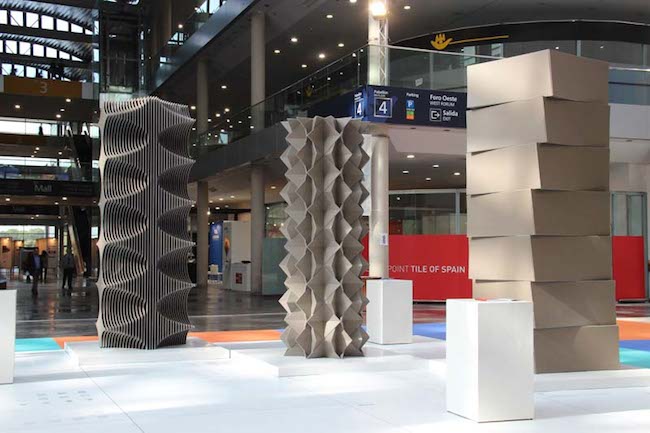

Pretty soon, thanks to Harvard, CFile will be able to write about ceramics in architecture that go beyond mere tile or cladding. MaP+S, Harvard’s Material Processes and Systems Group, showed off a bold new project at the Cevisama ceramics exhibition in Valencia, Spain this February. “Protoceramics” uses new technology to turn ceramics into structural objects.

According to its project page, Protoceramics is an ongoing experiment that seeks to produce ceramics that excel in “tectonic performance.” To achieve this, the ceramics are manipulated by cutting, folding and bending. The team “explores the inherent opportunities of these strategies towards the production of self-supporting assemblies.”

They state:

“Cutting takes advantage of digital fabrication equipment and the precision of computational modeling. Each contoured or perforated sheet in itself lacks the stiffness and stability to be self-supporting, but through connections with adjacent sheets gains enough rigidity to create stable structures. The removal operation of the cutting process is juxtaposed with the additive layering and assembly strategies which at times dissolves the individual sheet, almost pixelates the appearance, and in doing so transforms our perception of ‘ceramic tiles’. The exposed edges, normally carefully hidden, become the all-important focus.

“Folding takes advantage of the meshes bonded to the rear side of the ceramic elements, thus reversing the functional focus from the smooth front to a back that was not meant to be visible. By scoring the fold lines such as to leave the mesh intact a live hinge can be created. The ceramic sheets take on an origami-like quality while enabling an elegant way to create three-dimensional geometries on a large scale. Both modular as well as singular folded forms were studied. Some rely on aggregation patterns for stability, others derive their structural logic from inserted rigid frames or from folded edges being otherwise stiffened.

“Bending is maybe the least intuitive manipulation of a material commonly known to be brittle. Testing on small samples established safe cold bending radii and elastic material properties. Bending results in internal pre-stressing of the thin sheets, which in turn provides stiffness. The related assembly techniques combine individually bent ceramic tiles into unexpected material formations that defy conventional expectations in ceramic design.”

The exhibition at this year’s Cevisama displayed three large prototypes that are equal parts functional and aesthetically pleasing. These were supported with smaller, 3D printed models that show other design potentialities. We’re excited to see what can happen when ceramics, which can take on any number of unique shapes, are able to carry the entire structure of a building on their own. We can’t wait.

Any thoughts about this post? Share yours in the comment box below.

Add your valued opinion to this post.