We don’t need to sell you on ceramics. Though we’re mostly a contemporary ceramic art publication, the material has equally as many uses for technology. We try finding the most auspicious uses of ceramics in engineering and showcase them here, although our science knowledge is severely lacking.

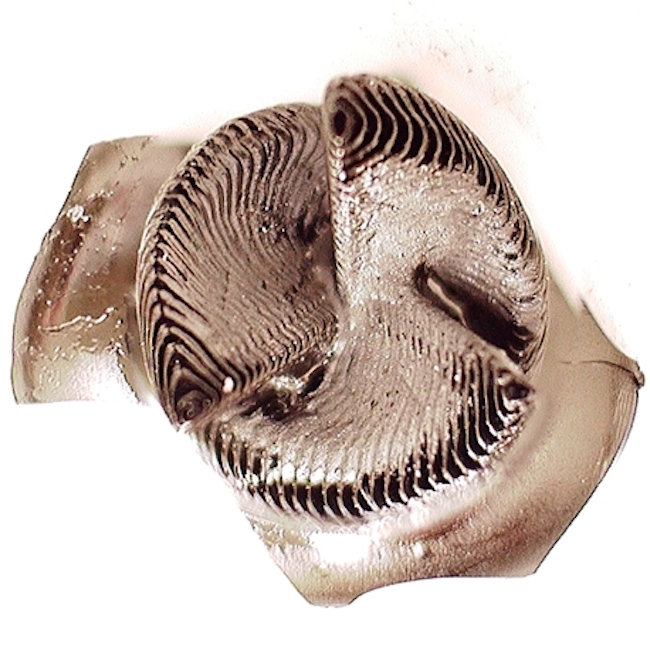

Above image: A ceramic corkscrew shape created using 3D printing. Image from HRL Laboratories, LLC. Read more about the designs here.

A theme we’ve noticed as we run these updates are researchers who circumvent the Achilles’ Heels of ceramics, namely it’s tendency to crack and it’s inflexibility. Scientists, apparently, have never heard of the adage “having your cake and eating it, too.”

We came across more news on that front this morning. Researchers are trying to harness ceramics’ high heat resistance for use in space flight and high-speed aircraft. Ceramics are a good fit for such aircraft because air resistance creates more heat as a ship travels faster through the atmosphere. Ceramic shells around such craft could solve that problem. If only there was a way to cast these ceramics as easily as metal or plastic. Oh well. Too bad. Let’s all go home.

According to Discovery, the idea is similar to ceramic tiles that once adorned space shuttles. However, the tiles were fragile and often needed to be replaced. Photograph courtesy of NASA.

Wait. Turns out we have that technology now: 3D printing. From Discovery’s Space page:

Ceramics are much more difficult to work with than plastics or metals because they cannot be cast or machined easily, according to Schaedler, who is an author on the new study appearing today in the journal Science.

But Schaedler’s team figured out how to trick ceramics into behaving like plastic.

“We have a pre-ceramic resin that you can print like a polymer, then you fire the polymer and it converts to a ceramic,” he said. “There is some shrinkage involved, but it’s very uniform so you can predict it.”

The big picture is that this method could help rocket and satellite designers who have to make lots of special small parts that are capable of resisting the heating that occurs during high velocity air friction, as well as high temperatures generated by the exhaust during takeoff.

A form of ceramic called alumina is being used in new ion propulsion drive, which uses electricity to heat gas and generate ions, according to Charlie Spahr, executive director of the American Ceramics Council.

“Ceramics are really good where you want to reduce wear and tear,” Spahr said.

The Pentagon’s research branch has been funding various projects to discover new ways to build lighter, stronger and more heat-resistant materials for aerospace and military applications.

“The method described in the new Science paper brings us closer to the goal of being able to ‘engineer in’ desired material properties that generally are not found together, such as strength and low density or low weight, and to craft these materials into complex shapes,” said Stefanie Tompkins, director of the Defense Science Office at the Defense Advanced Research Projects Agency (DARPA).

Figuring out how to make customized 3D-printed ceramic parts could also make a difference in gas-fired power plants, for example, or other types of gas engines, according to DARPA officials.

Love contemporary ceramic art + technology? Let us know in the comments.

Thank you for these updates on ceramics technology. I find them quite engaging!