The people over at The American Ceramic Society do a great job of illustrating hard-to-articulate concepts in materials science. For example, you may have noticed that over the years your laptops have become thin enough to shave with, but you can still wield your laptop’s brick-like power converter as a weapon if you’re ever assaulted in a Starbucks. Why is that?

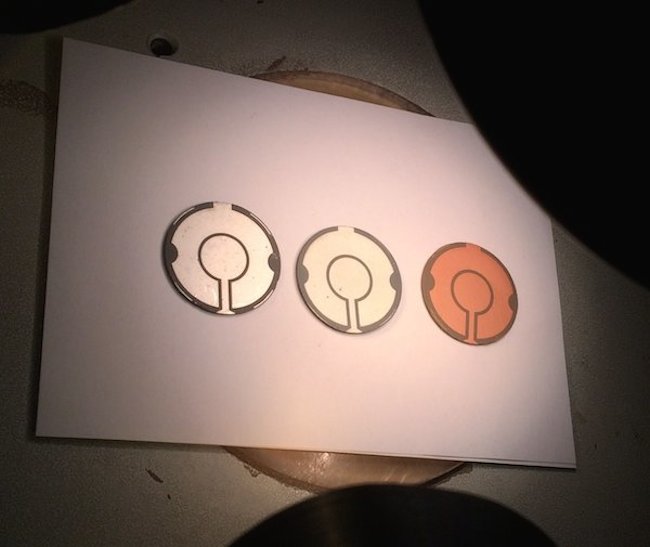

Above image: (From left to right) Multilayer piezoelectric transformers co-fired with platinum, silver–palladium (95/5), and copper electrodes.

We’re not shaming you. We think you’re beautiful just the way you are. We’re just wondering why you haven’t kept up with current tech trends.

According to materials researchers Erkan Gurdal, S. Tuncdemir and C.A. Randall, power converters remain the hulking monstrosities they are because of limitations of electromagnetic transformers, which make up the bulk of power converters. Inside the converter, electrical energy is converted to magnetic energy, where it passes through a magnetic core and changes back into electrical energy. This allows voltage to be adjusted on either side of the magnetic core. The converter heats up because some energy is lost in the conversion.

There may be another way to convert the energy feeding your laptop. Instead of electromagnetic transformers, we could use piezoelectric converters, which convert mechanical energy in the form of pressure into electrical energy. This structure uses a special kind of ceramic material.

Because piezoelectric materials can convert mechanical to electrical energy and vice versa, both conversions can be made within the material simultaneously by considering special designs. C. A. Rosen discovered piezoelectric transformers with PZT ceramics in the 1950s by designing a special electrode and polarization arrangement that could amplify the applied voltage significantly at the secondary side—called step-up.2 Accordingly, designs can also decrease voltage at the secondary side—called step-down.

Given the solid-state nature of piezoelectric transformers, their major advantage over electromagnetic transformers is high efficiency in ultra compact volumes (see comparison below).

Typical converters to the left and thinner PZT converters on the right. Photograph courtesy of Solid State Ceramics Inc.

The drawback is that these structures can be very costly to create (check out the materials in the cutline above). The researchers had to find a way to lower the temperature used to make hard PZT ceramics. This would allow them to design converters that use cheaper metals.

Our results show that by employing cheaper electrode materials—specifically base-metal electrodes like copper—it is possible to significantly reduce the cost of piezoelectric transformers so that they can compete with the cheaper price of electromagnetic transformers. Moreover, initial characterizations on copper co-fired multilayer transformers show significantly improved thermal and electrical behaviors compared to other materials, which should correlate with significant improvements in device performance.

This would mean that converters could be made lighter and more compact, small enough to fit inside a wallet, in fact. At that point converters will catch up with their more svelte cousins in the rest of the tech industry. For a bigger picture of this research, please visit the article here.

What do you think of this advancement in contemporary ceramics? Let us know in the comments.

Add your valued opinion to this post.